CAMPAGNOLO

Machines | Campagnolo

WHO WE ARE

Trusted name in the world of primary packaging machines.

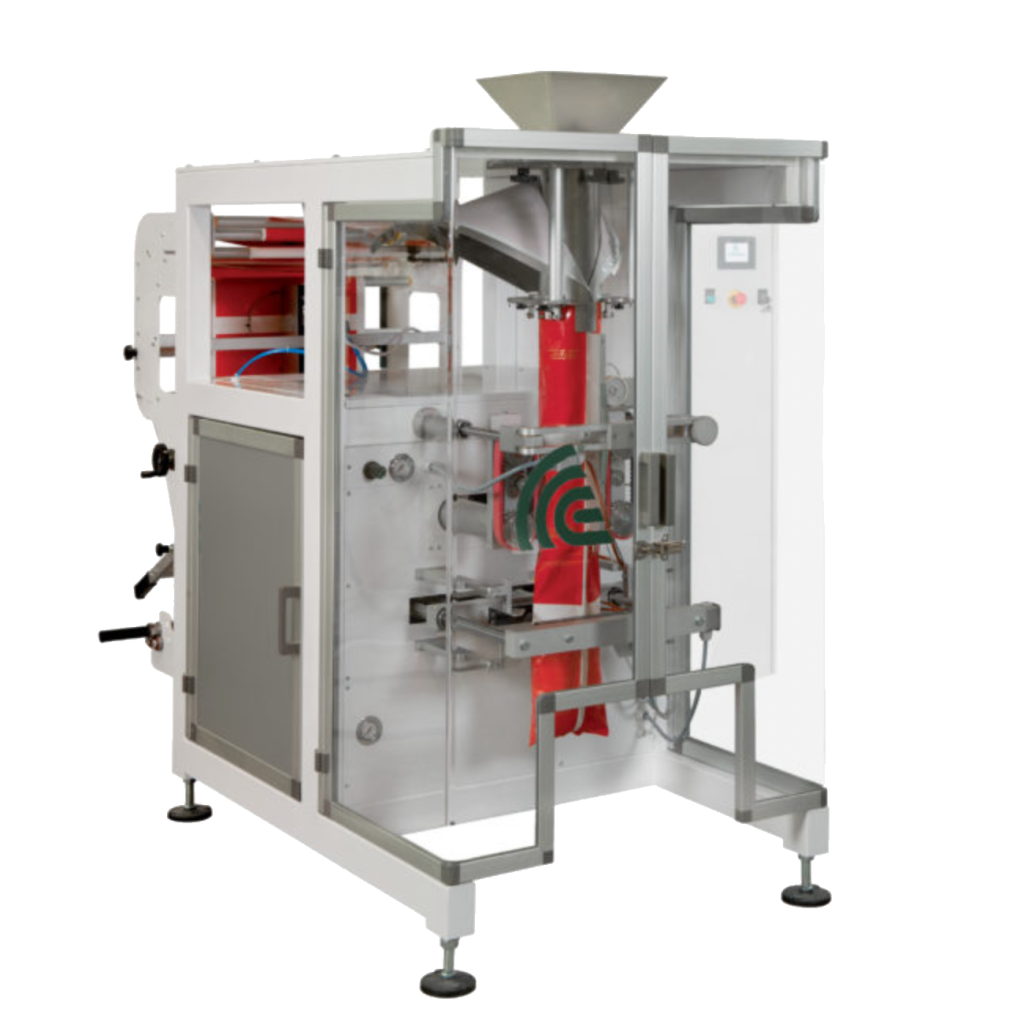

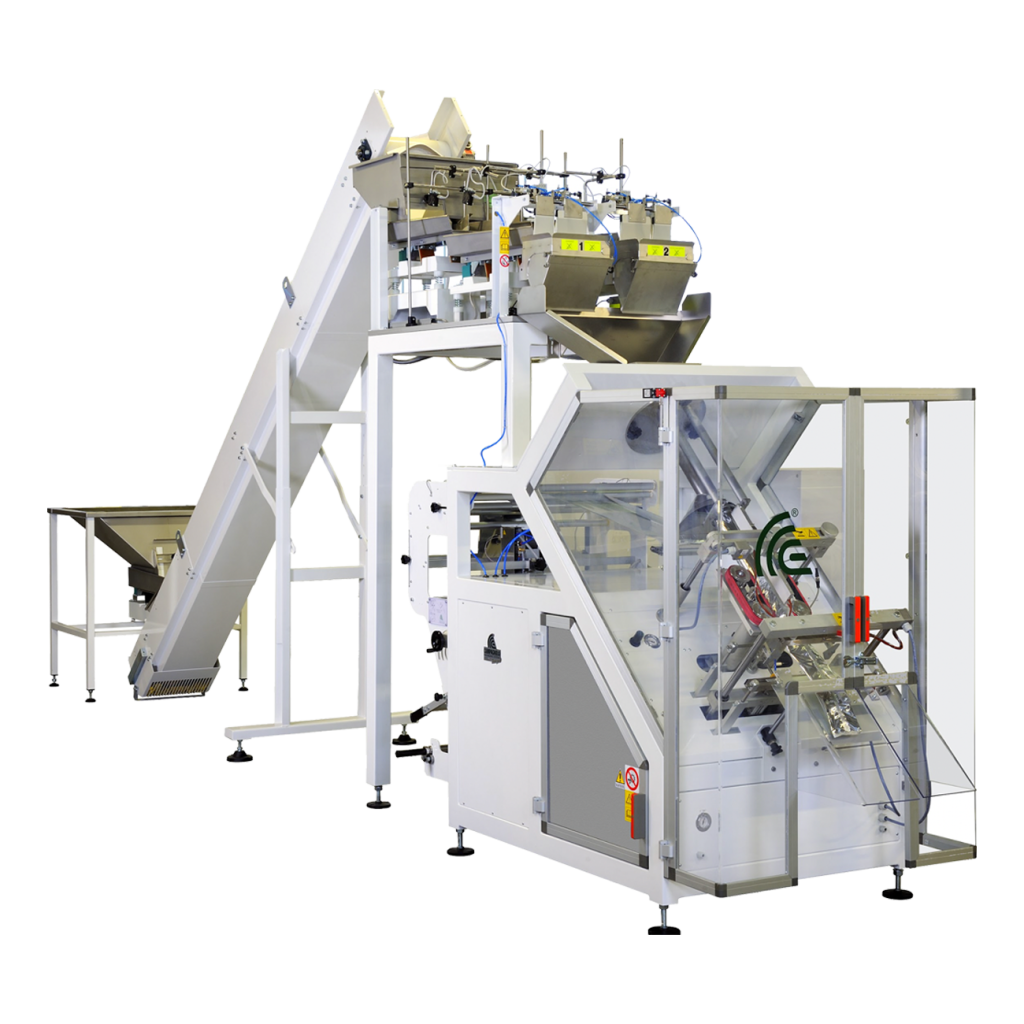

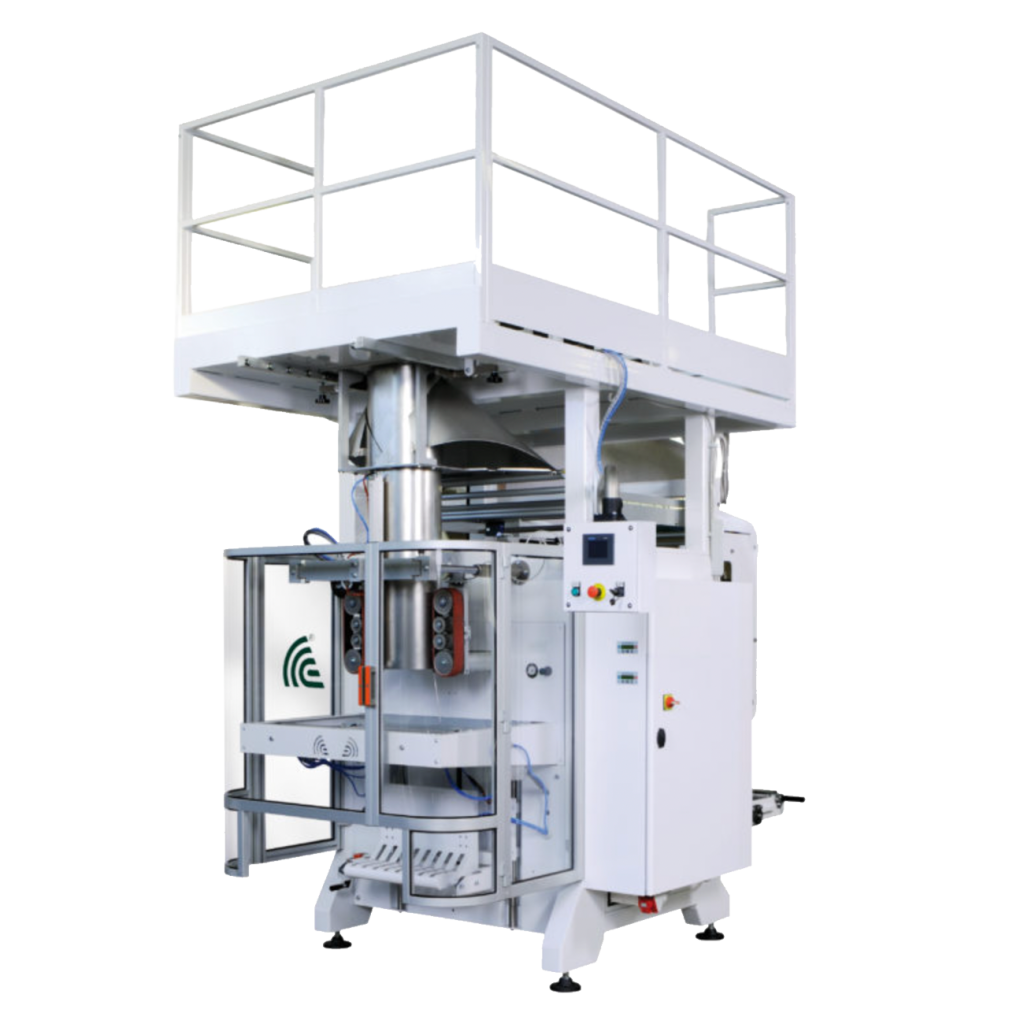

For over five decades, Campagnolo machines are the backbone of countless packaging operations, handling the intricate process of form-fill-seal with precision and efficiency. They expertly shape and seal bags of various sizes and shapes, catering to both food and non-food products alike.

WHAT SETS CAMPAGNOLO MACHINES APART

- Remarkable blend of human-centric design and cutting-edge technology. They’re built to withstand the rigors of daily operation, offering durability, reliability, and ease of use. Plus, they’re equipped with

- Advanced features. They ensure smooth and consistent performance, minimizing downtime and maximizing productivity.

But it’s not just about the technical specs – it’s about the tangible benefits they bring to your packaging process. With Campagnolo machines, you can count on consistent and high-quality packaging results, giving your products the protection and presentation they deserve.

When dealing with packaging your product(s), nothing is more important than feeling satisfied to have created an adequate embellishment. A wide range of accessories and feeding systems contributes to obtaining the required results. With Campagnolo by your side, you’ll have the tools you need to elevate your packaging game and leave a lasting impression on your customers.