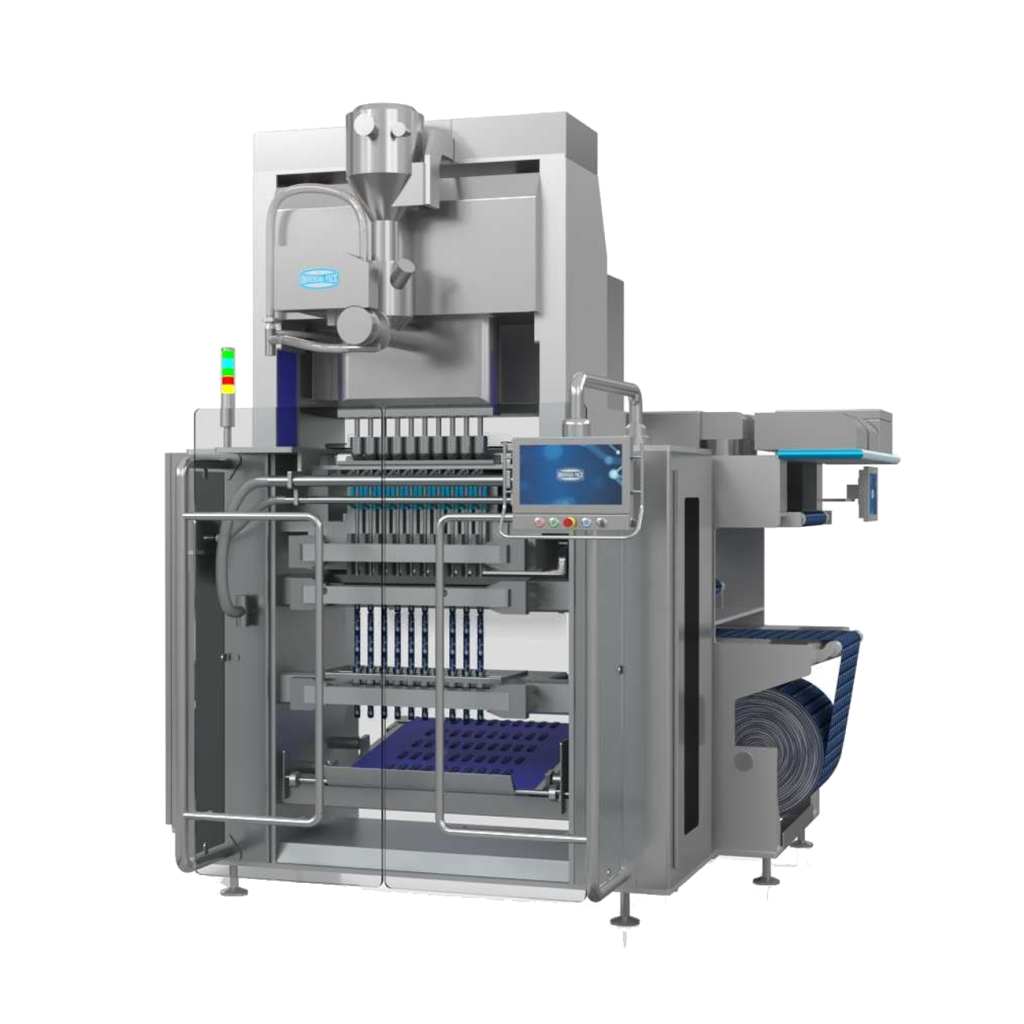

Stick Pack machine for powders

Technical parameters

Auger

Dry, dusty, & powdery free & non- free flowing products

Can be varied (Rational and turns of screw)

- Stick

- pillow pack

- standard

- lap seal

- PAP-PE (paper – polyethene)

- PAP-ALU ((paper – aluminum – polyethylene)

- PET-ALU-PE (polyethene terephthalate – aluminium – polyethene)

- PP (polypropylene)

- PLA (polylactic acid)

- PAP (paper), Bio-PE (bio-based polyethene),

Description

Our stick pack machines for powders provide a compact and efficient packaging solution, delivering high output while taking up minimal space. These machines come with several key benefits, such as precise dose accuracy, minimal wrapping material waste, and ease of handling and cleaning.

Our user-friendly, modular design allows you to minimize downtime and meet increasing production demands. The modular setup makes it easy to adjust and switch between different packaging needs quickly and without major interruptions. This flexibility is perfect for businesses aiming to streamline their operations and boost productivity.

Maintenance is straightforward with our machines. Their simple design ensures hassle-free cleaning and servicing, keeping your production line running smoothly with minimal disruptions.

In summary, our stick pack machines for powders offer a reliable, efficient, and user-friendly packaging solution. They help you maintain high production standards while reducing costs and downtime, making them a valuable addition to your packaging operations.

Stick pack machines

Where we supply

Kenya, Uganda, Tanzania, Rwanda, Burundi, South Sudan, Democratic Republic of the Congo (DRC)